Top US and European brands increasingly source their premium trousers from China. This shift occurs due to China’s compelling manufacturing and supply chain advantages. Modern corporate dress codes and advanced material science, like wrinkle-resistant fabrics, drive this. The decision reflects a strategic move. Brands leverage specific Chinese capabilities for high-quality production of their premium trousers.

Key Takeaways

- Chinese factories use advanced technology and skilled workers. They make high-quality trousers with great precision.

- Chinese manufacturers offer lower prices. They do this by using resources well. They still keep the quality high.

- China has a strong shipping system. This helps new trouser designs get to market quickly.

Unmatched Manufacturing Capabilities for Premium Trousers

Advanced Production Technology for Trousers

Chinese manufacturers invest heavily in cutting-edge production technology. They utilize advanced automation and digital pattern-making systems. These systems ensure precision and consistency in every garment. Rigorous quality control protocols are also in place. This technological edge allows for the creation of complex designs and high-quality finishes. It meets the demanding standards of premium apparel brands.

Highly Skilled Labor Force in Trousers Production

China possesses a vast and highly skilled labor force. These workers specialize in garment manufacturing. A leading Chinese facility, for example, employs 12,000 skilled individuals. This workforce handles a wide range of apparel. Their expertise ensures meticulous craftsmanship. They produce premium items, including sophisticated casual trousers. This large pool of talent maintains high production standards.

Efficient and Scalable Production of Trousers

Chinese factories offer remarkable efficiency and scalability. They meet varying demand levels. A single facility can boast a daily production capacity exceeding 100,000 pieces for general apparel. For premium streetwear, a manufacturer like Groovecolor achieves a monthly capacity of 300,000 pieces. They also provide flexible Minimum Order Quantities (MOQs) as low as 50-100 pieces per color. This allows brands to test market demand with small runs. Then, they can scale up production quickly without changing factories. China’s robust export infrastructure, including ports and logistics, further supports high-volume production and faster international shipping. This ensures rapid time to market for new collections of premium trousers.

Cost-Effectiveness Without Compromising Premium Trousers Quality

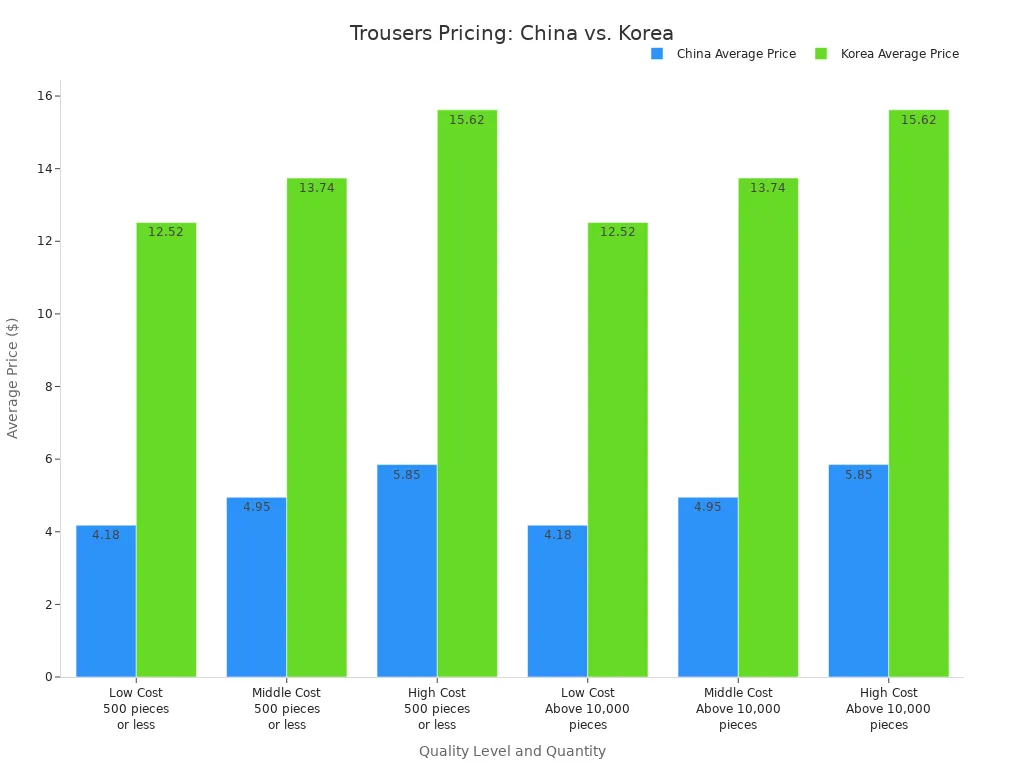

Competitive Pricing Structures for Trousers

Chinese manufacturers offer highly competitive pricing structures. This allows brands to achieve significant cost savings. For example, manufacturing costs for garments in China are considerably lower than in South Korea. The difference can be 2.6 to 3.5 times greater in Korea. This cost advantage is particularly noticeable for lower quality items and for both small and large order quantities.

| Quality Level | Quantity | China Average Price ($) | Korea Average Price ($) | Price Difference ($) |

|---|---|---|---|---|

| Low Cost | 500 pieces or less | 4.18 (range 3.23-4.67) | 12.52 (range 10.20-13.95) | 9.28 |

| Middle Cost | 500 pieces or less | 4.95 (range 3.97-5.60) | 13.74 (range 11.58-15.18) | 10.28 |

| High Cost | 500 pieces or less | 5.85 (range 4.63-6.51) | 15.62 (range 13.41-17.48) | 10.97 |

| Low Cost | Above 10,000 pieces | 4.18 (range 3.23-4.67) | 12.52 (range 10.20-13.95) | 6.97 |

| Middle Cost | Above 10,000 pieces | 4.95 (range 3.97-5.60) | 13.74 (range 11.58-15.18) | 7.61 |

| High Cost | Above 10,000 pieces | 5.85 (range 4.63-6.51) | 15.62 (range 13.41-17.48) | 8.78 |

This pricing strategy allows brands to maintain healthy profit margins. They do not compromise on the quality of their premium products.

Optimized Resource Utilization in Trousers Manufacturing

Chinese factories excel at optimizing resource utilization. This directly impacts overall production costs. They implement several strategies:

- Bulk Sourcing: Manufacturers minimize fabric costs. They purchase raw materials in large quantities from reliable suppliers.

- Lean Manufacturing Techniques: These techniques streamline processes. They reduce waste and improve operational efficiencies.

- Technological Advancements: Tools like CAD and automated cutting services enhance precision. They also reduce fabric waste. New textile technologies, such as laser distressing, decrease water and chemical usage. This lowers production costs and environmental impact.

- Sustainability: Adopting eco-friendly practices reduces waste and energy consumption. This results in long-term cost savings.

Value-Added Services for Premium Trousers

Beyond basic production, Chinese manufacturers offer extensive value-added services. These services enhance brand appeal and streamline development.

- Budget-Friendly Prototyping: Some manufacturers offer low entry points for sampling. This allows brands to test designs with minimal investment.

- Digital Mockups: Factories provide digital mockups. These are based on detailed customization briefs. This reduces ambiguity in early development stages.

- Private Labeling and Branded Packaging: Suppliers offer full branding integration. This includes woven or printed labels, custom hang tags, and branded polybags.

- Material Expertise and Sustainability: Manufacturers provide a wide range of fabrics. They also offer access to certified sustainable textiles and low-impact dyeing processes.

- Advanced Customization: Services include pattern development, label design, and fabric manipulation techniques. These comprehensive services shorten time-to-market for new collections.

Superior Supply Chain and Innovation in Trousers Manufacturing

Robust Logistics Infrastructure for Trousers

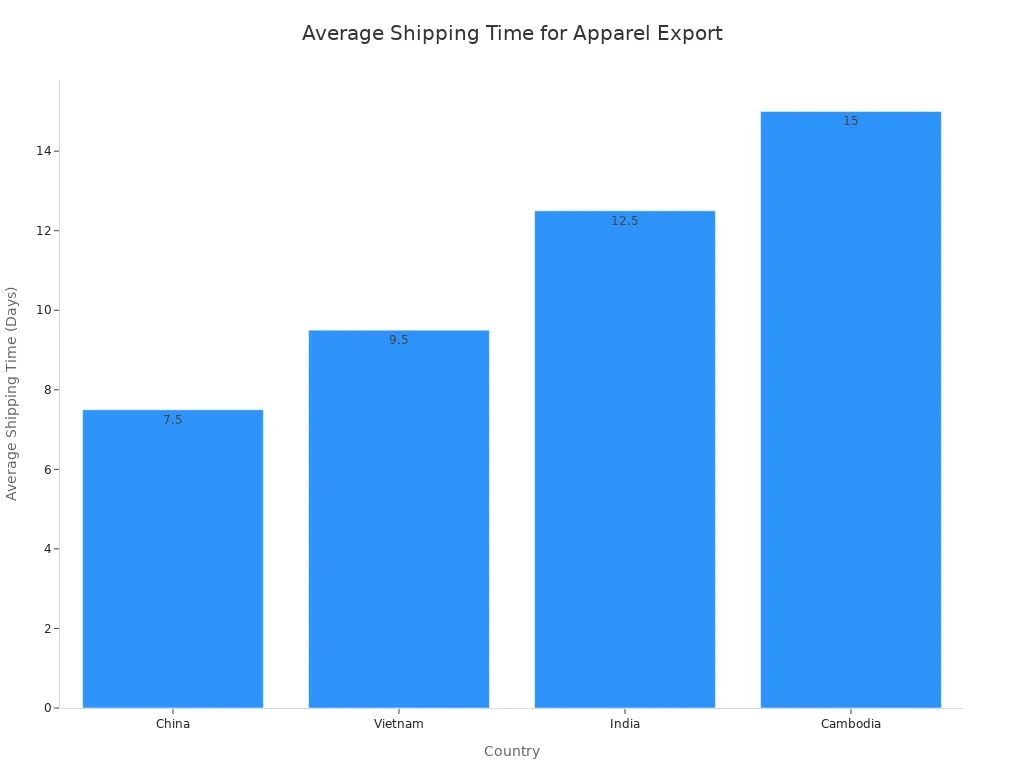

China possesses a robust logistics infrastructure. This infrastructure significantly supports premium apparel manufacturing. Major cities like Guangzhou and Ningbo feature leading ports. These ports offer frequent shipping routes to North America, Europe, and Australia. Their efficient customs offices minimize export delays. Shenzhen provides direct connectivity to Hong Kong. This facilitates rapid global shipping via sea and air. Hangzhou and Suzhou benefit from their proximity to Shanghai, China’s largest port. This ensures extensive global reach and competitive freight rates. China’s logistics infrastructure reduces delays and ensures reliable lead times for clothing production.

China’s logistics infrastructure is highly efficient for apparel export. It boasts very high reliability. Average shipping times are 5-10 days. This efficiency stems from its superior infrastructure, including extensive highways, high-speed railways, and major seaports.

| Country | Average Shipping Time (Days) | Logistics Reliability |

|---|---|---|

| China | 5–10 | Very High |

| Vietnam | 7–12 | High |

| India | 10–15 | Moderate |

| Cambodia | 12–18 | Developing |

This established network offers readily available materials and diversified options. It simplifies sourcing and reduces logistical complexities.

Rapid Time to Market for New Trousers Collections

Chinese factories enable rapid time to market for new collections. Their extensive manufacturing experience and vast supply chain are crucial. Maturing design and production capabilities lead to higher-quality products. This supports the growth of brands. Quick prototyping times are a key advantage.

| Factory Name | Quick Prototyping Time | Minimum Order Size (Pieces) |

|---|---|---|

| LeelineApparel | 7–10 days | 50 |

| JUAJEANS | 5-7 days | 300 |

| Hangzhou Mufan Clothing Co.,Ltd. | 7-12 working days | 500 |

| Guangzhou Cunzhuang Clothing Co.,Ltd. | 8-12 working days | 80 |

| Nien Hsing Textile | 10-14 days | 5,000 |

These rapid prototyping capabilities allow brands to test designs quickly. They can then scale production efficiently.

Material Science and R&D for Advanced Trousers Fabrics

Chinese manufacturers actively integrate material science and R&D into premium apparel development.

- Leading firms develop novel materials like chitosan-based fibers. They also advance dyeing techniques.

- Premium product development starts with high-quality, long-staple cotton. Manufacturers discuss differences in fabric types, yarn types, and fabric density.

- Master manufacturers pre-shrink or sanforize fabrics. This ensures dimensional stability. They provide data on expected shrinkage rates.

- They control for torque or skewing by managing knitting tension and implementing proper finishing processes.

- Structure in premium garments comes from high-density knitting, quality ribbing, and expert pattern cutting. This focuses on ‘hand feel,’ structure, and resilience.

- China’s linen industry uses automated fabric-cutting systems and AI-based pattern grading. This ensures precision fit, consistency, and reduced waste.

- Top factories provide material traceability through fiber origin certificates and testing reports.

- Fabric preparation involves professional pre-treatment to stabilize linen. This includes pre-shrinkage testing and color fastness analysis.

- Dyeing and washing innovations include low-impact, AZO-free dyes and enzyme washing. This demonstrates a commitment to sustainable practices.

- Chinese manufacturers possess innovation infrastructure, including R&D centers. They utilize advanced material development and technical expertise for complex designs.

Chinese manufacturing offers advanced capabilities, cost-efficiency, and excellent supply chains for premium trousers. Brands benefit from China’s comprehensive textile supply system, which keeps costs low. This strategic sourcing allows brands to maintain high quality while optimizing production. Chinese manufacturers are now key partners in high-end apparel, producing for global brands like Armani and GUCCI. This trend shows an evolving global landscape.

FAQ

What makes Chinese manufacturing superior for premium trousers?

Chinese factories use advanced technology and a highly skilled workforce. They offer efficient, scalable production. This ensures precision and consistency for premium apparel brands.

How do Chinese manufacturers maintain quality while offering competitive prices?

They optimize resource utilization through bulk sourcing and lean manufacturing. They also use advanced technology. This allows for cost savings without compromising the premium quality of trousers.

What supply chain advantages do Chinese manufacturers provide?

China has a robust logistics infrastructure. This includes major ports and efficient customs. It ensures rapid time to market for new collections and reliable lead times.

Post time: Jan-23-2026